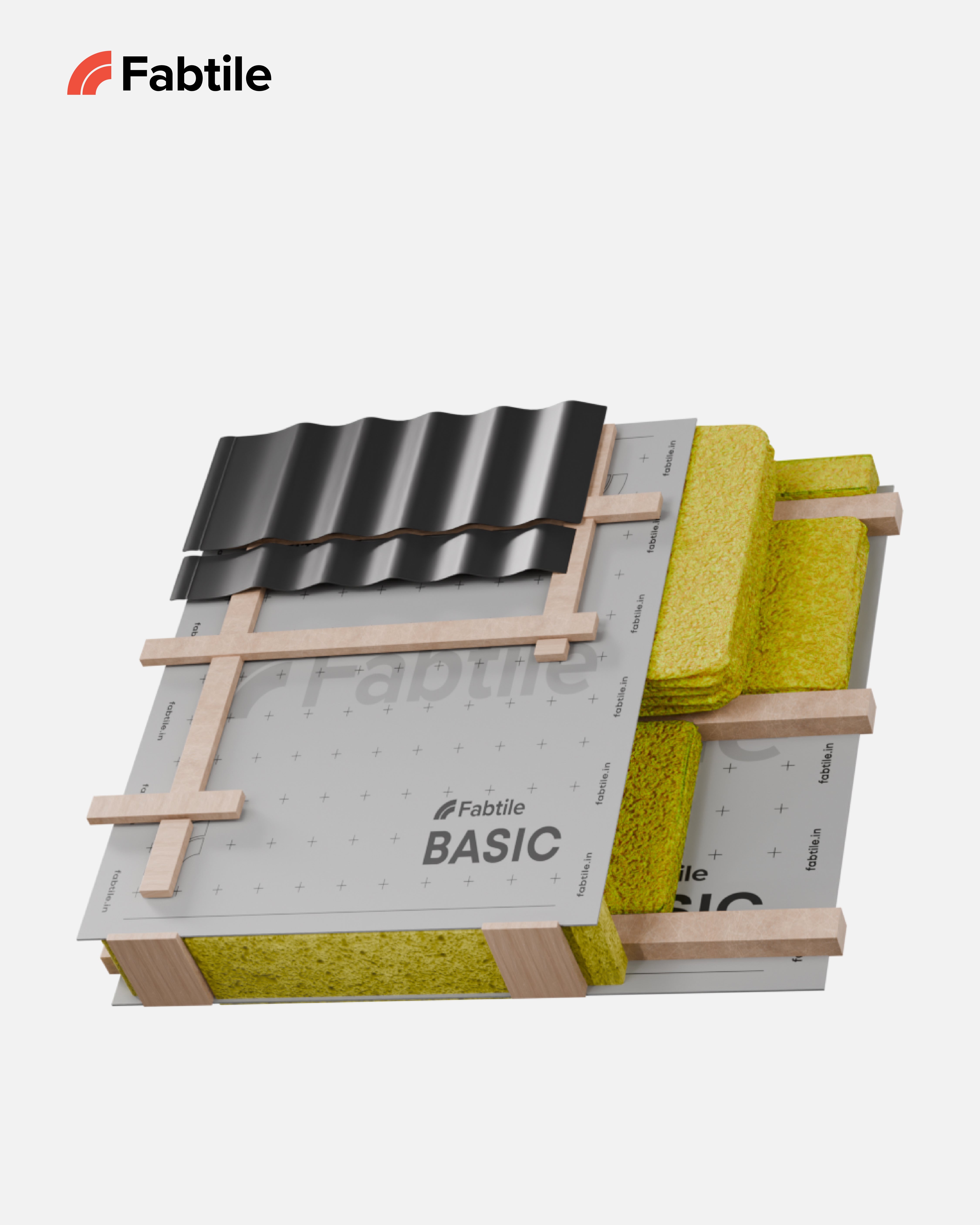

Ideal for insulated and ventilated sloping roofs without full sarking.

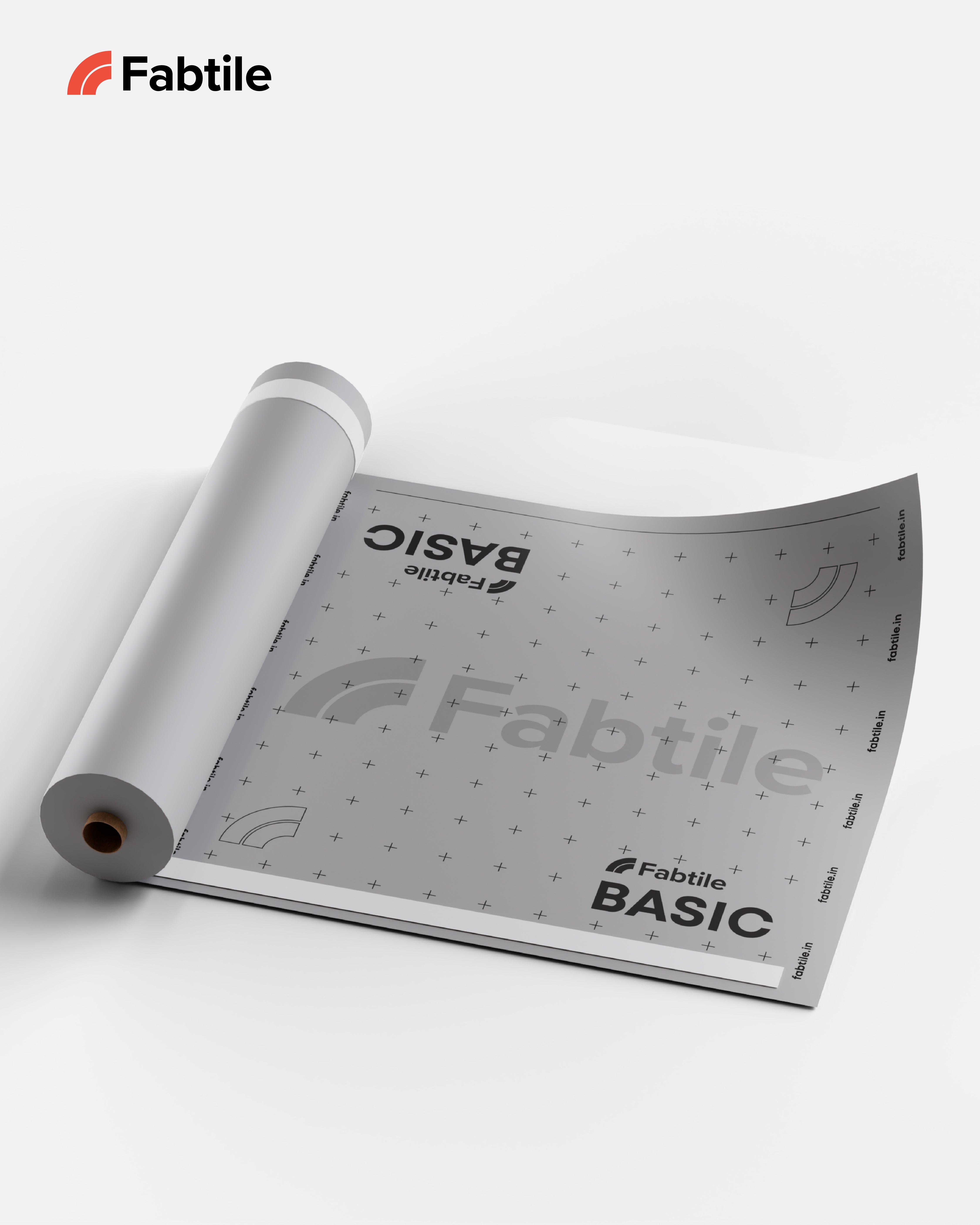

Fabtile Basic is a versatile, lightweight, three-layer breathable roofing membrane crafted for projects where moisture control and ventilation are essential. It combines high water resistance with excellent vapor permeability, making it perfect for small residential or lightweight commercial buildings. The membrane’s user-friendly installation and durability ensure it remains effective in diverse climates, providing long-lasting protection for your roofing structure.

Process Overview

Roof membranes are produced through a specialized laminated nonwoven process. Initially, spunbond polypropylene is created using the traditional spunbond method. This is followed by a lamination process, where a breathable film, made from either Polyethylene (PE) or Thermoplastic Polyurethane (TPU), is sandwiched between layers of nonwoven fabric. This unique structure provides both waterproofing and breathability, making it ideal for roofing applications.

Machines Used

- Spunbond Extrusion Machines: Create the nonwoven polypropylene layers.

- Lamination Machines: Bond the breathable film between the fabric layers.

- UV-Treatment and Heat-Sealing Systems: Ensure durability and waterproofing.

Technical Specifications

- GSM: 100–200 GSM

- Water Vapor Transmission Rate (WVTR): 1000–1200 g/m²/day

- Tensile Strength: 7–15 MPa (in machine and cross direction)

Applications

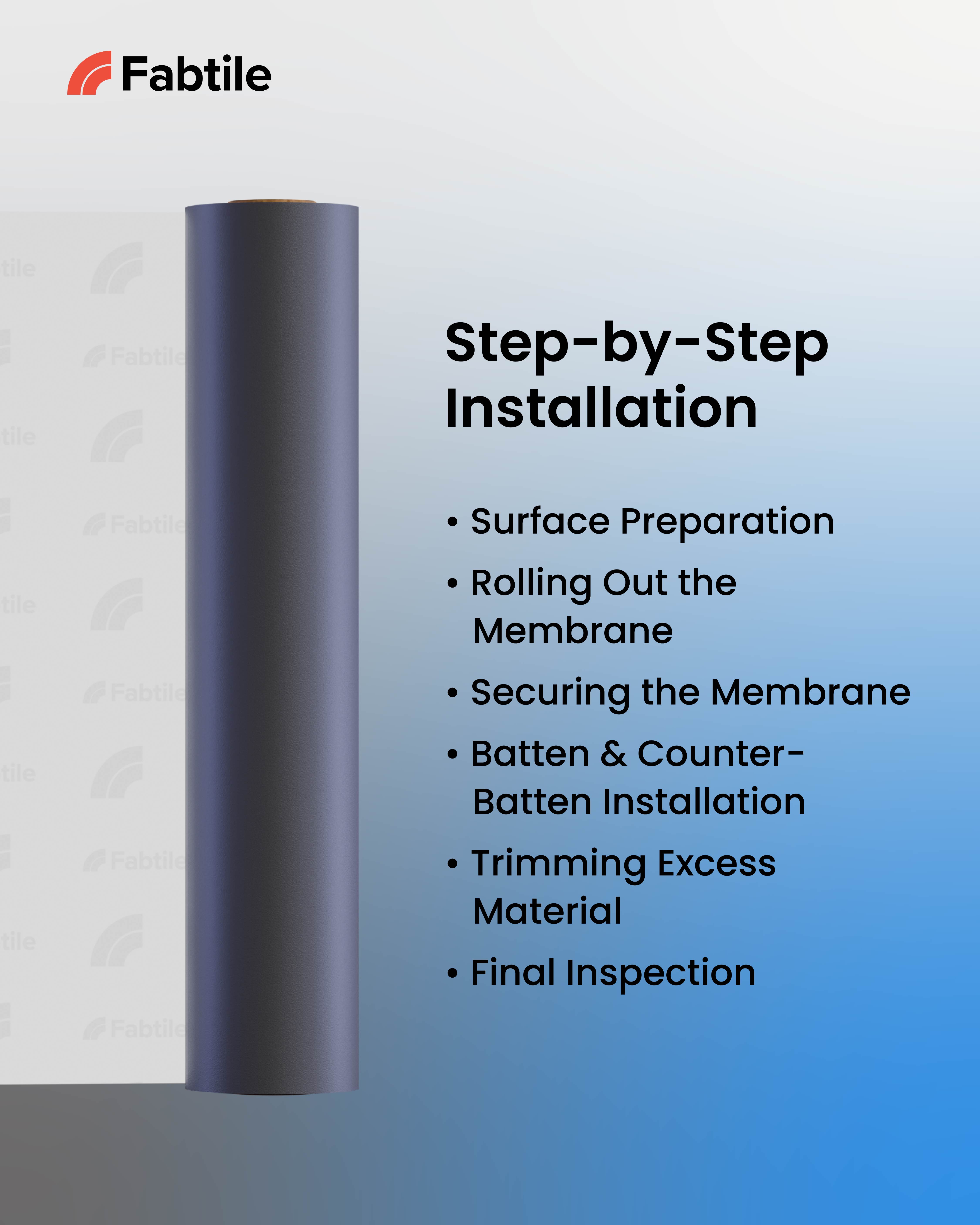

Installation Guide

Installation Instruction

- Work in dry conditions.

General Preparation

- Clear the roof area from debris and dust before applying the membrane.